Introducing the shim calculation formula for alignment, an essential tool in precision engineering, this article delves into the fundamentals of shim calculation, exploring its significance in achieving accurate alignment of machinery, equipment, and structures. By understanding the formula and its applications, engineers can optimize alignment processes, ensuring optimal performance and longevity of critical systems.

Shim calculation plays a pivotal role in various industries, including manufacturing, construction, and automotive, where precise alignment is paramount for proper functioning and safety. This article will provide a comprehensive overview of the shim calculation formula, its factors, materials, installation methods, and advanced techniques, empowering engineers with the knowledge and skills to confidently apply this formula in real-world scenarios.

Shim Calculation Formula Fundamentals

Shim calculation plays a crucial role in alignment, ensuring the proper positioning and functioning of machinery, equipment, and structures. It involves determining the thickness of shims, which are thin spacers used to adjust clearances and tolerances.

The basic formula for calculating shim thickness is:

Shim Thickness = (Tolerance + Clearance)

Actual Clearance

Factors Affecting Shim Calculation, Shim calculation formula for alignment

Several factors influence shim thickness calculations, including:

- Tolerance:The allowable variation in the dimensions of the mating parts.

- Clearance:The intentional gap between mating parts to allow for movement and lubrication.

- Alignment Specifications:The desired alignment parameters, such as parallelism, perpendicularity, and angularity.

Shim Materials and Types

Shims are typically made from various materials, each with unique properties and applications:

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, rigidity | Heavy machinery, power transmission |

| Brass | Corrosion resistance, low friction | Marine applications, electrical equipment |

| Aluminum | Lightweight, non-magnetic | Aerospace, electronic components |

| Composite | High strength-to-weight ratio, vibration damping | Automotive, medical devices |

Methods for Shim Installation

Shims can be installed using various methods, each with its advantages and disadvantages:

- Direct Insertion:Shims are placed directly between mating parts.

- Clamping:Shims are held in place using clamps or bolts.

- Adhesive:Shims are bonded to mating parts using an adhesive.

Step-by-Step Guide to Shim Installation:

- Measure the actual clearance.

- Calculate the required shim thickness.

- Select the appropriate shim material and type.

- Install the shim using the chosen method.

- Verify the alignment and adjust the shim thickness as needed.

Applications of Shim Calculation in Alignment

Shim calculation is used in numerous real-world applications, including:

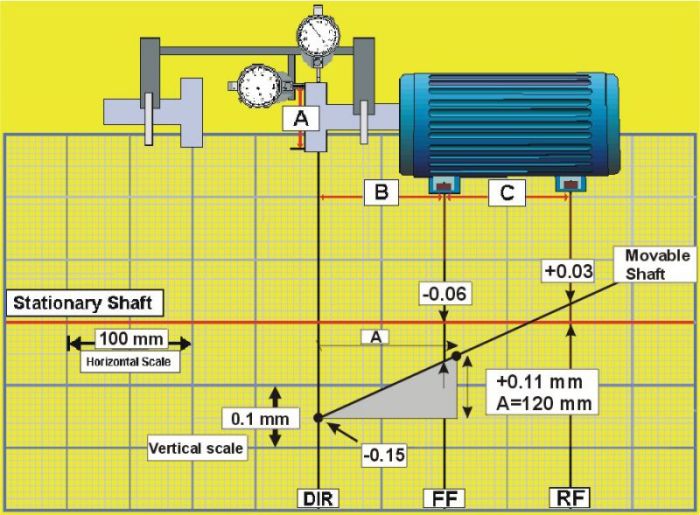

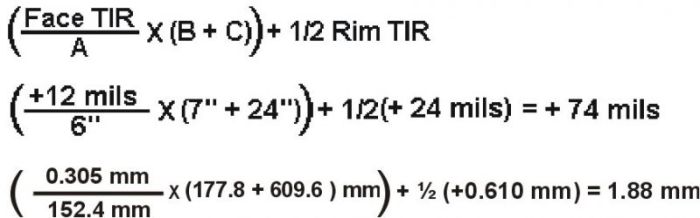

- Machinery Alignment:Ensuring proper alignment of shafts, gears, and other rotating components.

- Equipment Calibration:Adjusting the position of sensors, gauges, and other precision instruments.

- Structural Alignment:Leveling and aligning building frames, bridges, and other structures.

Advanced Techniques for Shim Calculation

Advanced techniques for shim calculation include:

- Spreadsheet and Software:Utilizing spreadsheets or dedicated software to automate calculations and improve accuracy.

- Statistical Analysis:Analyzing multiple measurements to determine the optimal shim thickness.

- Finite Element Analysis (FEA):Simulating the behavior of mating parts and shims under various loading conditions.

Tips for Optimizing Shim Calculation Accuracy and Efficiency:

- Use high-precision measuring instruments.

- Consider temperature effects on clearances.

- Verify alignment parameters before and after shim installation.

- Document all measurements and calculations for traceability.

FAQ Resource: Shim Calculation Formula For Alignment

What is the purpose of shim calculation?

Shim calculation determines the thickness of shims required to achieve precise alignment between two or more components or surfaces.

What factors influence shim thickness calculations?

Factors affecting shim thickness calculations include tolerance, clearance, alignment specifications, and the material properties of the shims.

What are the different methods for shim installation?

Common shim installation methods include direct placement, adhesive bonding, and mechanical fastening.

How can shim calculation improve alignment accuracy?

Shim calculation ensures that the correct shim thickness is used, minimizing alignment errors and optimizing the performance of aligned components.