If your truck has dual parking control valves, it’s crucial to understand their purpose, functionality, and maintenance requirements. This comprehensive guide delves into the intricacies of dual parking control valves, providing valuable insights for optimal truck performance and safety.

Dual parking control valves play a pivotal role in ensuring smooth and controlled parking operations for heavy-duty vehicles. By regulating air pressure to the truck’s brakes, these valves enable precise and responsive parking maneuvers, enhancing overall vehicle safety and efficiency.

Overview of Dual Parking Control Valves

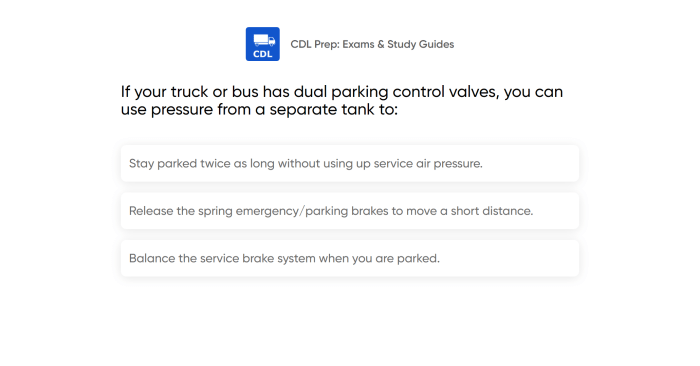

Dual parking control valves play a crucial role in ensuring the safe and efficient operation of heavy-duty vehicles with air brake systems. These valves are designed to control the application and release of air pressure to the parking brakes, providing a reliable and secure parking mechanism.

There are various types of dual parking control valves available, each with its unique design and functionality. Some common types include:

- Single-circuit valves: These valves control both front and rear parking brakes with a single air circuit.

- Dual-circuit valves: These valves provide separate air circuits for front and rear parking brakes, offering increased redundancy and safety.

- Spring-applied, air-released valves: These valves utilize a spring mechanism to apply the parking brakes and air pressure to release them.

Advantages of using dual parking control valves include:

- Enhanced safety: Redundant air circuits provide increased reliability and prevent brake failure in case of a single circuit failure.

- Improved performance: Dual valves offer more precise control over parking brake application and release, ensuring smooth and consistent operation.

- Reduced maintenance: With separate air circuits, maintenance and repair procedures can be performed on one circuit while the other remains operational.

However, there are also potential disadvantages to consider:

- Increased complexity: Dual valves require more complex plumbing and air lines, which can add to the overall cost and maintenance requirements.

- Potential for air leaks: The presence of additional air lines and connections increases the risk of air leaks, which can affect the effectiveness of the parking brakes.

Troubleshooting Dual Parking Control Valves

Common problems that can occur with dual parking control valves include:

- Parking brakes not engaging: This can be caused by air leaks, valve malfunctions, or insufficient air pressure.

- Parking brakes not releasing: This can be caused by valve sticking, frozen components, or excessive corrosion.

- Uneven brake application: This can be caused by unbalanced air pressure in the dual circuits or faulty valve operation.

To troubleshoot dual parking control valves, follow these steps:

- Check for air leaks: Use a soap solution to identify any leaks in the air lines or valve connections.

- Inspect the valves: Visually inspect the valves for any signs of damage, corrosion, or contamination.

- Test the valves: Use a brake tester to verify the proper operation of the valves, including application, release, and pressure regulation.

- Check the air pressure: Ensure that the air pressure in both circuits meets the manufacturer’s specifications.

- Lubricate the valves: If necessary, apply a suitable lubricant to the valve components to prevent sticking and improve operation.

- Regular maintenance: Perform regular inspections and maintenance according to the manufacturer’s recommendations.

- Protect from corrosion: Apply anti-corrosion coatings or treatments to the valves and air lines to prevent rust and corrosion.

- Use high-quality components: Choose high-quality valves and air lines to ensure durability and reliability.

- Visual inspections: Inspect the valves for any signs of damage, leaks, or corrosion on a regular basis.

- Functional testing: Perform functional tests to verify the proper operation of the valves, including application, release, and pressure regulation.

- Lubrication: Apply a suitable lubricant to the valve components to prevent sticking and improve operation.

- Air line inspection: Check the air lines for any signs of damage, leaks, or corrosion. Replace or repair as necessary.

- Air pressure check: Ensure that the air pressure in both circuits meets the manufacturer’s specifications.

- Proper installation: Ensure that the valves are installed correctly according to the manufacturer’s instructions.

- Secure air lines: Use appropriate clamps and fittings to secure the air lines and prevent leaks.

- Regular inspections: Conduct regular inspections to identify any potential hazards, such as leaks, corrosion, or damage.

- Test before use: Always test the valves before engaging the parking brakes to ensure proper operation.

- Avoid unauthorized modifications: Do not modify or alter the valves or air lines without consulting with a qualified technician.

To prevent problems with dual parking control valves, consider the following tips:

Maintaining Dual Parking Control Valves

To ensure the optimal performance and longevity of dual parking control valves, establish a regular maintenance schedule. This schedule should include the following tasks:

If any problems are identified during maintenance, refer to the troubleshooting guide or consult with a qualified technician for further diagnosis and repair.

Safety Considerations for Dual Parking Control Valves: If Your Truck Has Dual Parking Control Valves

To ensure the safe operation of dual parking control valves, consider the following safety precautions:

By following these safety considerations, you can minimize the risks associated with dual parking control valves and ensure the safe operation of heavy-duty vehicles.

Key Questions Answered

What are the common problems associated with dual parking control valves?

Common problems include leaks, corrosion, and contamination, which can affect valve operation and lead to parking system malfunctions.

How can I troubleshoot issues with dual parking control valves?

Troubleshooting involves identifying symptoms, checking air pressure, inspecting valves for leaks or damage, and verifying electrical connections.

What is the recommended maintenance schedule for dual parking control valves?

Regular maintenance includes periodic inspections, cleaning, lubrication, and replacement of worn components as needed.