Conical vial with spin vane – Conical vials with spin vanes have revolutionized sample preparation, offering unparalleled efficiency and versatility in laboratory and industrial settings. These vials, equipped with an ingenious spinning mechanism, ensure thorough mixing and prevent sample loss, making them indispensable tools for researchers, quality control professionals, and environmentalists alike.

Their unique design and wide range of applications make conical vials with spin vanes an essential component of modern scientific and industrial practices. This comprehensive guide delves into the intricacies of these vials, exploring their advantages, limitations, and the latest advancements shaping their future.

Conical Vial Overview

A conical vial is a laboratory glassware commonly used in chemistry and biology. It is characterized by its conical shape, with a narrow bottom and a wider opening at the top.

Conical vials are typically made of borosilicate glass, which is resistant to heat and chemicals. They come in various sizes, ranging from a few milliliters to several liters. The most common size is the 15 mL conical vial.

Purpose and Applications

Conical vials are used for a variety of purposes, including:

- Preparing and mixing solutions

- Heating and cooling solutions

- Storing solutions

- Centrifuging solutions

- Performing titrations

Spin Vane Characteristics

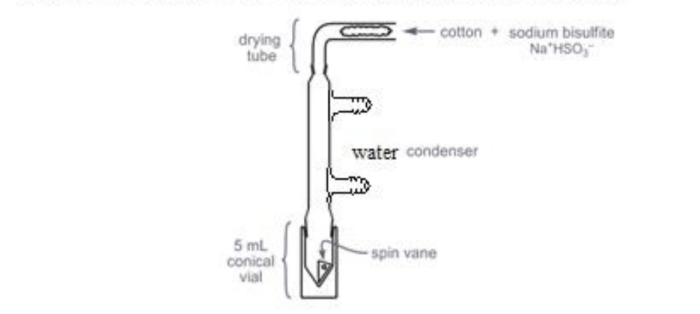

The spin vane, an indispensable component of the conical vial, is a strategically positioned element that plays a crucial role in enhancing mixing efficiency and safeguarding sample integrity. This unique device boasts a distinctive structure that optimizes its functionality within the vial’s confines.

Composed of a durable material, typically inert plastic, the spin vane is carefully designed to fit snugly within the conical vial’s base. Its shape resembles a miniature propeller, featuring several angled blades that extend outwards from a central hub. These blades are meticulously crafted to create a vortex effect when the vial is agitated.

Vortex Generation

The spin vane’s primary function lies in its ability to generate a vigorous vortex within the liquid sample. As the vial undergoes agitation, either manually or through mechanical means, the spin vane’s blades swiftly rotate, creating a powerful centrifugal force that propels the liquid outwards from the center.

This outward flow encounters the vial’s walls, causing the liquid to circulate back towards the center. The continuous circulation induced by the vortex ensures thorough mixing of the sample, eliminating concentration gradients and promoting uniform distribution of components.

Sample Retention

In addition to enhancing mixing efficiency, the spin vane also serves as a crucial safeguard against sample loss. Its strategic placement at the base of the vial prevents the formation of a stagnant zone where particles could settle and potentially be lost during decanting or pipetting.

The constant agitation created by the spin vane ensures that all particles remain suspended within the liquid, preventing them from adhering to the vial’s walls or forming undesirable precipitates. This feature is particularly valuable for samples containing valuable or sensitive components that require precise handling and accurate analysis.

Applications in Various Industries

Conical vials with spin vanes find diverse applications across a wide range of industries due to their versatility and effectiveness in sample preparation, mixing, and analysis.

In laboratory settings, these vials are extensively used in chemistry, biology, and pharmaceutical research for various tasks, including sample preparation, mixing, and reaction optimization. The spin vane helps ensure thorough mixing, even with viscous samples, and facilitates efficient resuspension of precipitates or cell pellets.

Industrial Applications

Beyond laboratory settings, conical vials with spin vanes are also employed in numerous industrial sectors, including manufacturing, quality control, and environmental monitoring.

- Manufacturing:In manufacturing, these vials are used for quality control testing of raw materials and finished products, ensuring compliance with industry standards and specifications.

- Environmental Monitoring:In environmental monitoring, conical vials with spin vanes are used to collect and analyze water, soil, and air samples for various contaminants, aiding in the assessment of environmental health and compliance with regulatory standards.

Advantages and Limitations

The integration of spin vanes within conical vials offers numerous advantages, primarily in the realm of sample preparation and analysis. These advantages stem from the unique design of the spin vanes and their interaction with the vial’s conical shape.

Enhanced Mixing

The presence of spin vanes within conical vials significantly improves the mixing efficiency of liquids or solutions. The vanes’ rotation creates a vortex-like motion within the vial, which facilitates the thorough and rapid distribution of reagents or analytes throughout the sample.

This enhanced mixing capability is particularly advantageous in applications where rapid and uniform mixing is crucial, such as in immunoassays or enzymatic reactions.

Reduced Sample Loss

The conical shape of the vial, coupled with the spin vanes, minimizes sample loss during mixing or agitation. The conical bottom of the vial ensures that the liquid is effectively directed towards the center, reducing the likelihood of sample splashing or spilling.

Additionally, the spin vanes help prevent the formation of air bubbles, which can interfere with mixing and lead to sample loss.

Ease of Use

Conical vials with spin vanes are designed for ease of use in a variety of laboratory settings. The vials are typically made of durable materials, such as polypropylene or polystyrene, which can withstand centrifugation and other handling procedures. The spin vanes are also designed to be easily inserted and removed, allowing for quick and convenient cleaning and maintenance.

Conical vials with spin vanes are handy lab equipment, facilitating efficient mixing and aeration. In life, like in the essay Regret for the Past by Lu Xun, we sometimes ponder over past actions, but like the spin vane, we must continue our journey, learning from our experiences and striving for a better future.

Despite their numerous advantages, conical vials with spin vanes may have certain limitations or potential drawbacks:

Potential Drawbacks

- Cost:Conical vials with spin vanes can be more expensive than traditional conical vials without vanes.

- Compatibility:The spin vanes may not be compatible with all types of laboratory equipment, such as certain centrifuges or vortex mixers.

- Cleaning:The spin vanes may require additional cleaning and maintenance to prevent contamination or buildup of materials.

Overall, the advantages of using conical vials with spin vanes often outweigh the potential limitations. The enhanced mixing, reduced sample loss, and ease of use make these vials a valuable tool for a wide range of laboratory applications.

Design Considerations

Designing conical vials with spin vanes requires careful consideration of several factors to ensure optimal performance and efficiency. These include the vial size, spin vane dimensions, and material compatibility.

Optimizing the spin vane design is crucial for efficient mixing and sample retention. The spin vane’s shape, size, and orientation should be carefully engineered to generate sufficient centrifugal force to mix the sample effectively while minimizing sample loss due to splashing or foaming.

Vial Size

The vial size directly influences the spin vane dimensions and the overall efficiency of the mixing process. Larger vials require larger spin vanes to generate sufficient centrifugal force, while smaller vials can accommodate smaller spin vanes. The vial size should be carefully selected based on the sample volume and the desired mixing intensity.

Spin Vane Dimensions

The dimensions of the spin vane, including its diameter, length, and thickness, play a vital role in mixing efficiency. The spin vane should be large enough to generate sufficient centrifugal force but not so large that it impedes sample loading or retrieval.

The length and thickness of the spin vane should be optimized to minimize sample splashing and foaming while ensuring adequate mixing.

Material Compatibility

The materials used for the conical vial and spin vane should be compatible with the sample and the mixing process. The materials should be chemically inert, non-toxic, and resistant to wear and corrosion. The spin vane should be made of a material that is strong enough to withstand the centrifugal forces generated during mixing.

Manufacturing Processes: Conical Vial With Spin Vane

Conical vials with spin vanes are typically manufactured using a combination of molding and assembly processes. The vial body is usually molded from a thermoplastic material, such as polypropylene or polyethylene. The spin vane is typically made of a metal or ceramic material and is inserted into the vial body during assembly.

Quality control measures are implemented throughout the manufacturing process to ensure that the vials meet industry standards. These measures include:

- Inspection of raw materials

- Monitoring of molding and assembly processes

- Testing of finished products

By following these quality control measures, manufacturers can ensure that conical vials with spin vanes meet the high standards required for use in various industries.

Molding

The vial body is typically molded using a process called injection molding. In this process, molten plastic is injected into a mold cavity. The mold cavity is shaped to create the desired shape of the vial body. Once the plastic has cooled and solidified, the mold is opened and the vial body is ejected.

Assembly, Conical vial with spin vane

The spin vane is typically inserted into the vial body during an assembly process. The spin vane is held in place by a variety of methods, such as adhesives, press-fitting, or ultrasonic welding.

Quality Control

Quality control measures are implemented throughout the manufacturing process to ensure that the vials meet industry standards. These measures include:

- Inspection of raw materials: The raw materials used to manufacture the vials are inspected to ensure that they meet the required specifications.

- Monitoring of molding and assembly processes: The molding and assembly processes are monitored to ensure that they are operating within the required parameters.

- Testing of finished products: The finished vials are tested to ensure that they meet the required performance specifications.

By following these quality control measures, manufacturers can ensure that conical vials with spin vanes meet the high standards required for use in various industries.

Safety and Handling Guidelines

To ensure safe handling and storage of conical vials with spin vanes, adhering to specific guidelines is crucial. Improper handling poses potential hazards that can be effectively mitigated by following these guidelines.

Storage

- Store vials in a clean, dry, and well-ventilated area.

- Avoid exposure to extreme temperatures, moisture, or corrosive substances.

- Secure vials upright in suitable racks or containers to prevent damage or contamination.

Handling

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses when handling vials.

- Inspect vials for any cracks, chips, or damage before use.

- Handle vials carefully to avoid spills or breakage.

- Dispose of used vials and spin vanes properly according to laboratory waste disposal protocols.

Potential Hazards

Improper handling can lead to hazards such as:

- Spillage of hazardous contents due to breakage.

- Exposure to sharp edges or broken glass.

- Contamination of samples or the work environment.

Case Studies and Applications

Conical vials with spin vanes have found wide applications across various industries, enabling efficient mixing and aeration in diverse settings. Let’s explore some notable case studies that showcase their successful use.

One prominent application is in the pharmaceutical industry, where conical vials are employed for cell culture and biopharmaceutical production. The spin vane’s ability to create a uniform and controlled mixing environment enhances cell growth and productivity, leading to improved yield and quality of the final product.

Case Study: Pharmaceutical Production

In a specific case study, a leading pharmaceutical company utilized conical vials with spin vanes for large-scale cell culture. The spin vanes provided gentle and consistent agitation, ensuring optimal oxygen transfer and nutrient distribution throughout the culture medium. This resulted in a significant increase in cell viability and productivity, enabling the company to meet the growing demand for their biopharmaceutical products.

Future Trends and Innovations

The future of conical vials with spin vanes holds exciting possibilities for advancements in design, materials, and applications. As technology continues to evolve, we can expect to see new innovations that enhance their performance and expand their use in various industries.

Novel Materials and Designs

Research and development efforts are focused on exploring novel materials and designs to improve the efficiency and durability of conical vials with spin vanes. Advanced polymers and composite materials are being investigated for their lightweight, corrosion resistance, and enhanced thermal properties.

These materials can enable the creation of vials that are lighter, stronger, and better suited for demanding applications. Additionally, innovative designs are being explored to optimize the geometry of the spin vane, reducing turbulence and improving mixing efficiency.

Smart and Connected Vials

The integration of smart technologies into conical vials with spin vanes is a promising area of innovation. By incorporating sensors and wireless connectivity, vials can become “smart” devices that provide real-time monitoring of mixing processes. This enables remote monitoring, automated control, and data analysis, allowing for improved process optimization and quality control.

Smart vials can also be connected to cloud-based platforms, facilitating data sharing and collaboration among multiple users.

Applications in Emerging Industries

As the capabilities of conical vials with spin vanes continue to expand, their applications are likely to extend into emerging industries. These vials could play a crucial role in the development of advanced materials, such as nanomaterials and biomaterials, where precise mixing and controlled reactions are essential.

They may also find applications in microfluidics, where precise fluid manipulation is required, and in the pharmaceutical industry, where efficient mixing is critical for drug manufacturing and delivery.

FAQ Resource

What are the primary advantages of using conical vials with spin vanes?

Conical vials with spin vanes offer several key advantages, including improved mixing efficiency, reduced sample loss, ease of use, and compatibility with a wide range of sample types.

How do spin vanes enhance mixing efficiency?

Spin vanes create a vortex within the vial, promoting thorough mixing and ensuring that all components of the sample are evenly distributed.

What are the potential limitations of using conical vials with spin vanes?

While conical vials with spin vanes offer numerous benefits, they may not be suitable for all applications. Factors such as sample viscosity, volume, and the presence of delicate components can影響 their effectiveness.